From Space Camp to Designing Airplane Parts: The Making of an Aerospace Nerd

Christina Kurth’s career journey started with a visit to Kennedy Space Center in elementary school and a summer at Space Camp, propelling her towards a lifelong passion for all things aerospace and a calling to fulfill her ultimate dream of becoming an astronaut. While the call from NASA hasn’t happened yet, the call from The Barnes Global Advisors (TBGA) brought her into a new world where she could apply her passion for flight and design in an entirely new way.

The journey began after receiving her Aerospace Engineering degree from Carlton University in Canada, sending her to the Bombardier subsidiary of de Havilland, where she learned advanced design from some of the best in the business. Curious about the possibilities of using topology-optimized software, she designed a bracket that was perfectly balanced for strength and weight, then calculated the potential fuel savings if applied throughout the aircraft fuselage. Excited by the concept, she brought the design to her boss, who immediately led her down to the shop floor. There, surrounded by the hum of machines and the insight of seasoned machinists, she learned why the bracket couldn’t be manufactured using traditional machining or casting methods. It was a humbling moment – the software was ready, but the manufacturing processes were not. That moment stuck with her. Years later, TBGA Founder John Barnes would call it the “Bracket of the Future” in a Voices Amplified Podcast—a nod to the lesson that shaped her journey into additive manufacturing.

Life moved forward, and so did Christina. After getting married and relocating to South Florida, she joined Embraer Executive Jets, transitioning from engineering to sales engineering. During this time, she learned about Sintavia – a local, vertically integrated contract manufacturer producing topology-optimized parts for aerospace using laser powder bed fusion. For Christina, Sintavia was the missing link in her bracket story—the moment when the dream caught up with reality. The software had been ready back then; now, FINALLY, the manufacturing capabilities were too.

Joining Sintavia launched her into additive manufacturing, where she collaborated closely with sales, operations, and technical teams to identify applications, qualify parts, and navigate the certification process. It was incredibly fulfilling for her to see innovative designs come to life, pushing the boundaries of advanced manufacturing.

Today, Christina continues her advanced manufacturing journey at TBGA, joining a team that has been certifying metal additive parts for commercial aircraft since 2003. She now works alongside individuals whose expertise spans decades, from assisting in the Columbia disaster response to qualifying the first Airbus additive part, and supporting recovery efforts after the Deepwater Horizon disaster. Rather than focusing on one technology, she now assesses optimal manufacturing solutions for each unique application, leveraging the team’s lessons learned to deliver successful, collaborative projects.

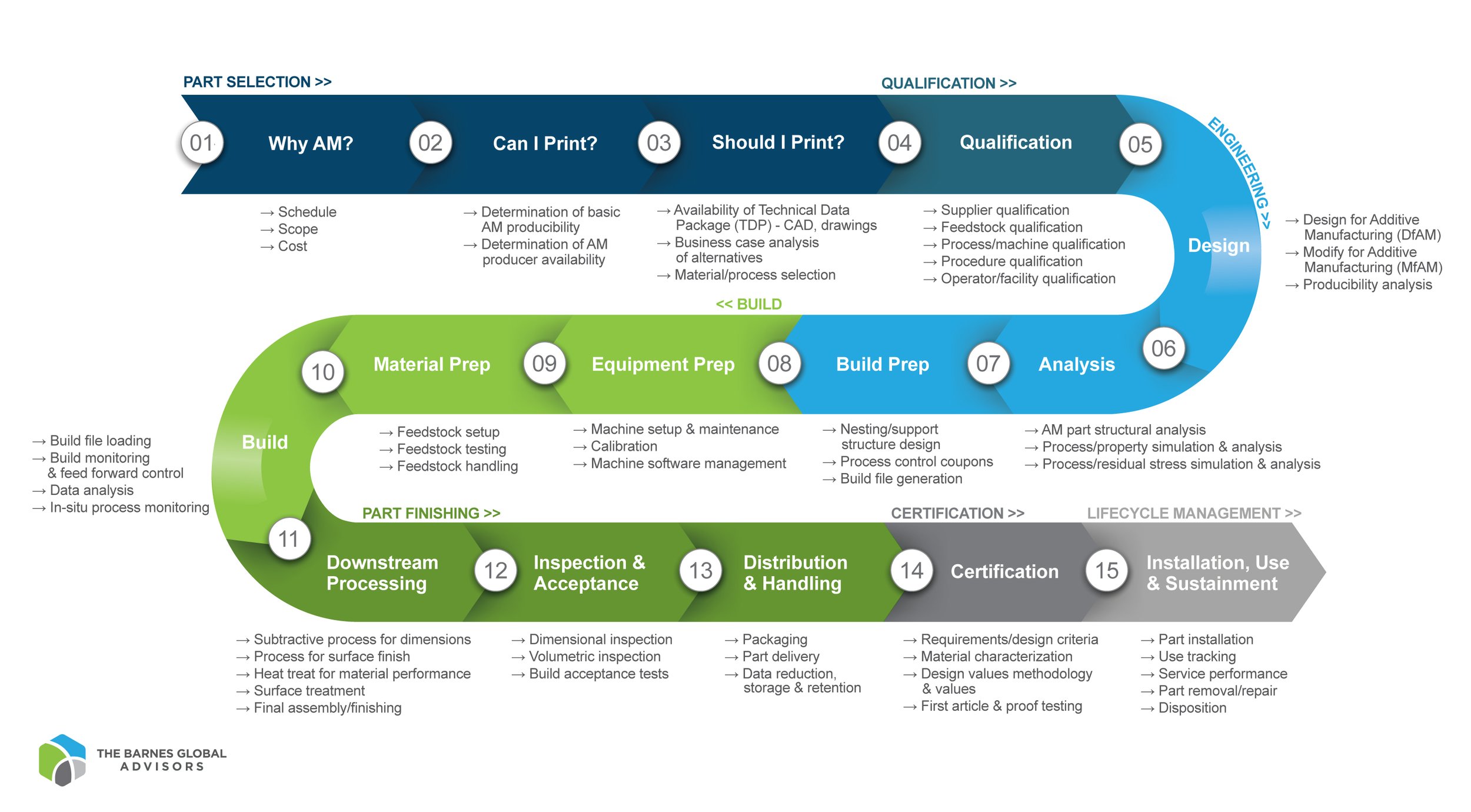

She is excited to be able to access the powerful tools developed by TBGA to support additive decision-making, in particular the Value-Chain “snake” graphic. This framework begins with part selection, prompting critical questions like “Why are we using AM?” and “Should we use AM?” to ensure users are pursuing parts with real value. It then guides teams through each stage: qualification, engineering, finishing, certification, and lifecycle management.

TBGA is committed to elevating the industry by sharing knowledge, empowering others with the tools to succeed, and fostering growth through collaboration. For Christina, the “Bracket of the Future” represents a vision brought to life—delivering tangible value to the industry. The future is now, and collaboration is key to advancing additive technologies.